Fluid Conveyings

People, passion and solutions are the strong features of O+P. For more than 40 years we have been producing equipment for hydraulic pipelines, offering customized solutions gained from research, precision and quality. Wideness of range, development and innovation make O+P a unique, young and dynamic brand. Manufactured in compliance with EC standards, all our products ensure quality, innovation and safety which are the results of the fact that all the mechanical components used in our equipment are manufactured by our sister company Sinde Srl, specifically set up for this purpose making it a critical piece to O+P’s consistent quality.

Crimping

The OP crimping machines are specialized tools designed for crimping hydraulic hoses and fittings. They are known for their precision, durability, and efficiency in assembling hoses for industrial and hydraulic applications. OP offers a range of models, from compact portable machines to advanced electronic systems, suitable for various hose sizes and types.

Cutting

OP cutting machines are designed for precision cutting of hydraulic hoses and other materials. They are equipped with features like serrated blades, safety guards, and optional measuring devices to ensure accurate and efficient cuts.

Fitting Assembly

Designed to achieve a perfect fitting preassembling on hoses (up to 8" in diameter) before crimping.

Skiving

OP skiving machines are designed for precise skiving of hydraulic hoses, allowing for the removal of the outer and inner layers of the hose to prepare it for crimping. These machines are equipped with features like double cutters for external skiving and single cutters for internal skiving.

Marking

Device for marking ferrules up to a 2’’ diameter.

Accesories

Designed to complement and enhance the functionality of OP machines, like winding/rewinding device, hose carrier, hose holder, etc.

Washing

Equipment for the internal cleaning of flexible hoses. Cleaning operations are carried out by means of a spray gun, which introduces a specific solvent into the hose. The detergent action of the solvent combines with the pressure that develops inside the component to eliminate any deposits possibly accumulated therein.

Testing

Specialized machines designed for testing hydraulic and industrial hoses. They are used to ensure the safety and reliability of hose assemblies by performing tests like pressure testing, burst testing, and impulse testing.

Multi-functional Unit

Versatile machines designed for processing rigid hydraulic tubes. They can perform multiple operations such as deburring, bending, pre-assembling DIN2353 rings, and flaring of stainless steel and carbon steel tubes.

Bending

Bending machine is ideal for bending stainless steel (AISI 316 TI) and carbon steel (ST 37.4) rigid tubes.

Pre-assembling

Machines designed for DIN2353 cutting rings pre-assembly and 37° JIC flaring of hydraulic rigid tubes.

37° 90° FLARING

Machines for orbital flaring of hydraulic rigid tube ends. These machines use a cold orbital forming process to create smooth and precise sealing surfaces at both 37° and 90°, ensuring compatibility with O-Ring seals.

Deburring

Machine carries out both internal and external deburring of rigid tubes in stainless (AISI 316 TI) and carbon steel (ST 37.4).

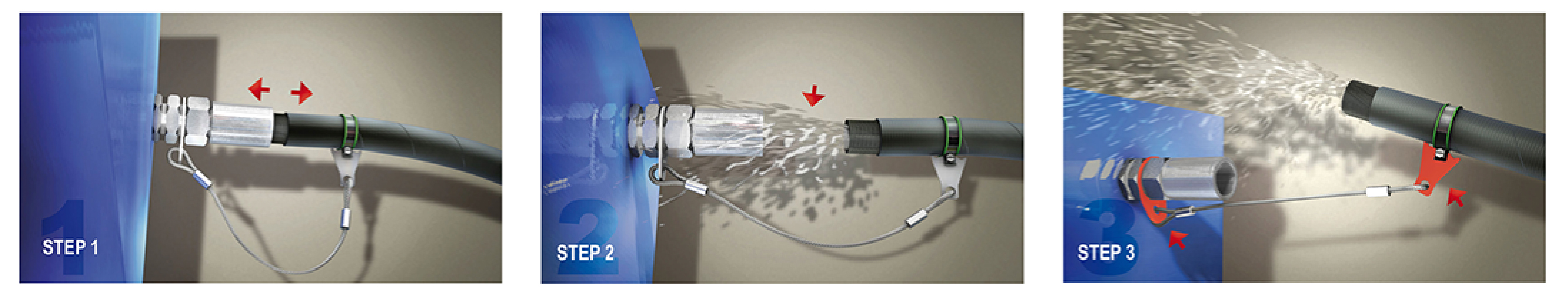

Stopflex

The Stopflex retention system is designed to arrest the trajectory of the flexible hose in case of disconnection of the fitting, avoiding the dangerous “whip effect” caused by the energy released. As a matter of fact, thanks to the Stopflex system, the hose is secured to the plant by means of a cable protecting both the operators and components.

Hydropower

We design and produce advanced test benches for industrial, automotive, and aerospace applications. Known for excellence and innovation, Hydropower excels in creating custom solutions for the most specific and complex customers needs. Our expertise covers mechanical and electrical design, fluid dynamics, and software development. We manage all production phases internally, ensuring quality and reliability.

Mobile Hose Workshop

The OP Mobile Hose Workshop is a fully equipped container for hose assembly. This innovative solution finds its perfect application in building sites, the construction industry and all those situations requiring an assistance centre always close at hand.